- Determine the nutritional needs of your fish.

Different types of fish require different amounts of nutrients, so it’s important to know the nutrients and proportions of your fish, which is the foundation of floating fish feed, for example.

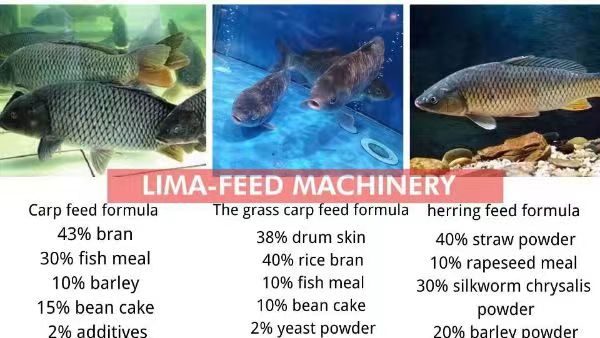

the main nutritional components of the basic floating fish feed formulation

bran 60%

fish meal 30%

yeast meal 5%

various minerals and vitamins 5%

adhesive a small amount of aqueous solution of wheat flour is added

The requirement of protein, fat, carbohydrate, vitamins, and minerals for different species of fish varied significantly. Understanding the nutritional needs and preferences of fish is the key to producing high-quality and fish-friendly feed. If you don’t understand, you can ask China Lima Feed Machinery Manufacturing Company for 24-hour customer service. The basic nutritional requirements of fish include the following aspects: protein: protein is one of the essential nutrients for fish growth and development. The different stages of fish growth, and the different types of fish, all affect its growth needs of protein content, for example, with the predatory nature of fish feed needs more protein content, during the growth of fish, fat is essential, it affects the energy of fish, is an essential source of energy, fatty acids are important, content is very important, control of the feed of various raw materials is also very important ohCarbohydrates: carbohydrates are also an important source of energy for fish. Fish need the right amount of carbohydrates to meet their energy needs for life and growth. Vitamins and minerals are essential for healthy growth and micronutrients. They can strengthen the immune system of fish and ensure their normal physiological functions, the development of fish bones and scales is determined by minerals

2. Choose the right raw materials

according to their own fish’s nutritional needs and dietary preferences, choose the right raw materials. Common raw materials are fish meal, soybean meal, corn flour, wheat flour, vegetable oil, vitamins, and minerals.

Grass carp feed ingredients are mainly bean cake, rice bran, fish meal, and wheat bran. Animal feed. The main components of goldfish feed are red worms, water fleas, and Cyclops plant feed. For example, there are wiping, aquatic plants, and goldfish for omnivorous fish, like water fleas, water earthworms, and other live bait. However, the source of live food is limited, so dry fish insects are generally used instead, if there is complete nutrition artificial synthetic feed can also be fed.

Fishmeal, for example, is an important source of protein. It is a powder produced by processing fish with specialized equipment. Fish meal is rich in protein and essential amino acids for fish growth. It is also an important source of protein. Wheat flour is a common carbohydrate source used by feed manufacturers.

3. Raw material proportioning

To fully understand the suitable fish feed formula, the purchase, and raw material formula need to be strictly proportioned, proportion is very important, unclear can consult the transportation material proportioning experts, or visit the Processing Machinery Company official website manual customer service, for example, Lima Feed Processing and Manufacturing Company

They can provide you with the right proportions based on specific factors, such as growth stage and speed, species, and agricultural environment, and the accuracy of your fish feed formula ratios affects the success of high-quality pelagic fish feed production, in consultation, give detailed information to help experts make specific and detailed judgments

4. Preparation of raw materials

the required raw materials will be sorted, prepared, and ensured that they are dry and free of impurities, to avoid the impact of feed health, use, and other issues.

In the preparation of raw materials in the process there are a number of points to note, in the next tells you to clean and disinfect: in the preparation of raw materials, there is a need to ensure that all used containers, tools, and feed manufacturing equipment are thoroughly cleaned and disinfected to prevent cross-contamination and bacterial growth. The dryness of fish feed is very important. Recommend using feed drying machine In the environment without drying, the feed will produce bacteria, which will cause fish to get sick and infected with bacteria. In serious cases, it will cause large-scale fish death, common air drying machines or fans, as well as natural air drying, to dry thoroughly. Screening and impurity removal: Use a feed impurity removal machine, screening and impurity removal of raw materials, and fully remove any impurities, and foreign matter, to ensure the quality and purity of the final feed. Good storage: pre-prepared raw materials will be stored in a dry, cool place in a good environment, and ensure that it is kept, sealed, to avoid moisture and pests.

5. Mix the ingredients with Lima mixer

place the ingredients in a Lima mixing machine to ensure that they are clean, dry, and free of impurities, and gradually mix them to ensure that they are evenly mixed.

In the mixing process, we should pay attention to: mixing time: to ensure that each raw material is fully mixed, mixing time and speed should refer to the material and quantity of change. Mixing order and direction: according to the formula, gradually add mixed raw materials. Ensure uniform mixing, in the process to avoid certain raw materials too much or insufficient. Appropriate temperature adjustment: in the mixing process, the wrong temperature may lead to the consumption of some nutrients and raw material mixing uniformity.

Recommended China Lima mixer

In the selection of mixing machines, I recommend the Chinese Lima mixing machine. Its advantage is that it can mix different materials well, and its production efficiency is higher than most of the company’s mechanical equipment, the quality of the products is also quite good. Using the Chinese Lima mixing machine, your production efficiency can be improved, and the product quality is also guaranteed. In addition, the Lima mixing machine can adjust the mixing time and speed, more suitable for different feed production needs, also suitable for different process requirements, it is recommended that the Lima mixing machine is easy to operate, if you want to learn how to use the process also has a dedicated customer service online 24 hours, China Lima machinery has reliable after-sales service, and quite reliable product quality, maintenance of the machine and regular cleaning is also very easy. Lima believes that trust comes from the quality of the company’s philosophy, every machine will be used before the test machine, to ensure that the hands of customers are able to use a good machine, careful attitude, and good service so that Lima’s loyal customers continue to increase,

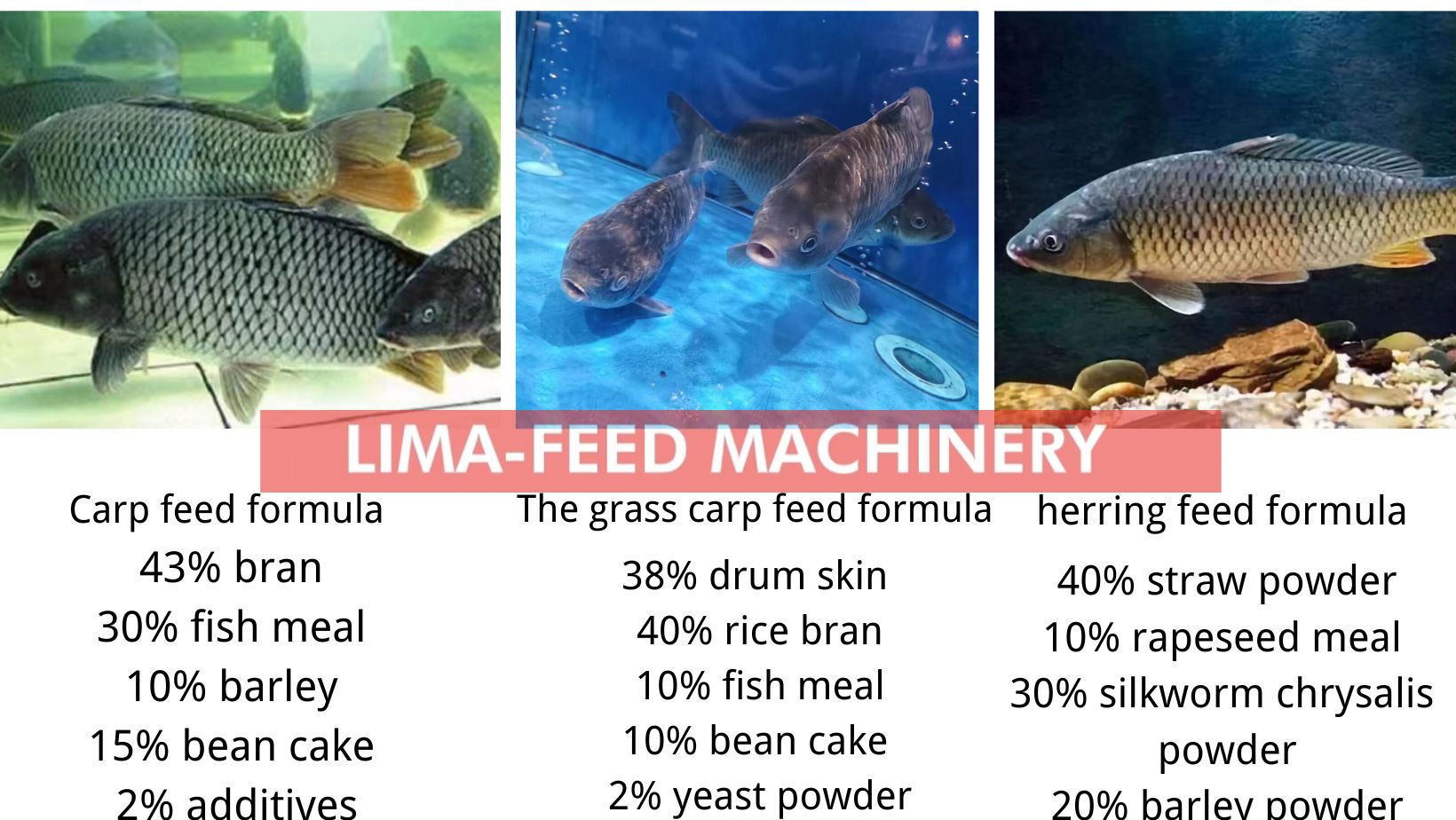

6. Granulation & pre-drying and drying with Lima granulator

The mixture is pelleted with a ChinaLima professional granulation machine. If you don’t know how to choose the right equipment, you can go to the official website of major machinery manufacturing companies to see if there are suitable equipment for your needs, the pelleting can press the feed into the pellet shape you want, which is convenient for your fish to eat, and also has the advantages of improving the stability and shelf life of the feed. The mixture can be compressed into pellets of the desired shape and size using a fish feed pelletizer or mold to reference the state and size of your fish. The production of pellets of the right size to facilitate the normal digestion of fish, to avoid causing larger particles, and fish indigestion problems, the pellet feed production process needs to be placed in a well-ventilated, suitable environment pre-drying place, to remove excess moisture. Then, put it into the drying equipment, with the appropriate temperature and time to dry, ensure that the feed is dry and stableRemember to add the right amount of pure water: according to the scientific feed formula, in order to add the right amount of pure water, so that the mixture of raw materials become wet.

I recommend that you use the Lima granulation machine. The reason Lima machine lets customers choose is that during the process of granulation, Lima machine will squeeze raw materials into particles at high temperatures, lima pelletizing machine in the pelletizing process has realized the function of high-temperature disinfection, and also played the role of drying feed, killing two birds with one stone, it can eliminate some bacteria, better guarantee the quality of fish feed, in addition, Lima pelletizing machine pressure particles are relatively solid, can increase the daily intake of fish, so that fish get enough nutrients every day, more conducive to the growth of fish and healthy life.

7. China lima Quality control&store &packing

In the production of pelagic fish feed, quality inspection is very important. The quality inspection may take the sampling to carry on the examination method, the examination feeds each kind of nutrition material content and the nature that conforms to the standard request. We can also evaluate the quality of feed by observing its color, smell, and texture. after the feed is thoroughly cooled, store it in a clean, dry, cool place to avoid moisture and mold growth, affecting the normal use of feed and fish health.

Packaging is also a key factor that affects whether the feed can be used. If the wrong packaging happens to leak or break, the hard-made feed will be wasted, so once the feed quality is confirmed to be up to standard, can be packaged. Immediately select the appropriate packaging materials to ensure that the feed in the storage and transport process does not occur in case of contamination and damage. Of course, high safety can also be taken in sealed packaging, sealed packaging can extend the preservation of feed, and to some extent improve the degree of fresh feed.

Warm Tips,

These are the general steps and examples for producing floating fish feed. If you want more detailed and accurate information, you can refer to Lima’s official website or Consult Lima Feed Equipment Company’s 24-hour online customer service to analyze the specific situation and practices, making their own floating fish feed is healthy, additives less, nutrient-rich, the advantage of using different raw materials to make floating fish feed that is more suitable for your own fish is that you have to take every step seriously, no mistakes, after the completion of the production must be tested in their own fish to eat. Be sure to check the package for air leaks before using it. Rupture and other conditions, the production of strict fish feed has a profound impact on the health of fish. This article is over, I hope you can help in their own production of floating fish feed problems, I wish you a successful and suitable for their own floating fish feed, thank you for browsing