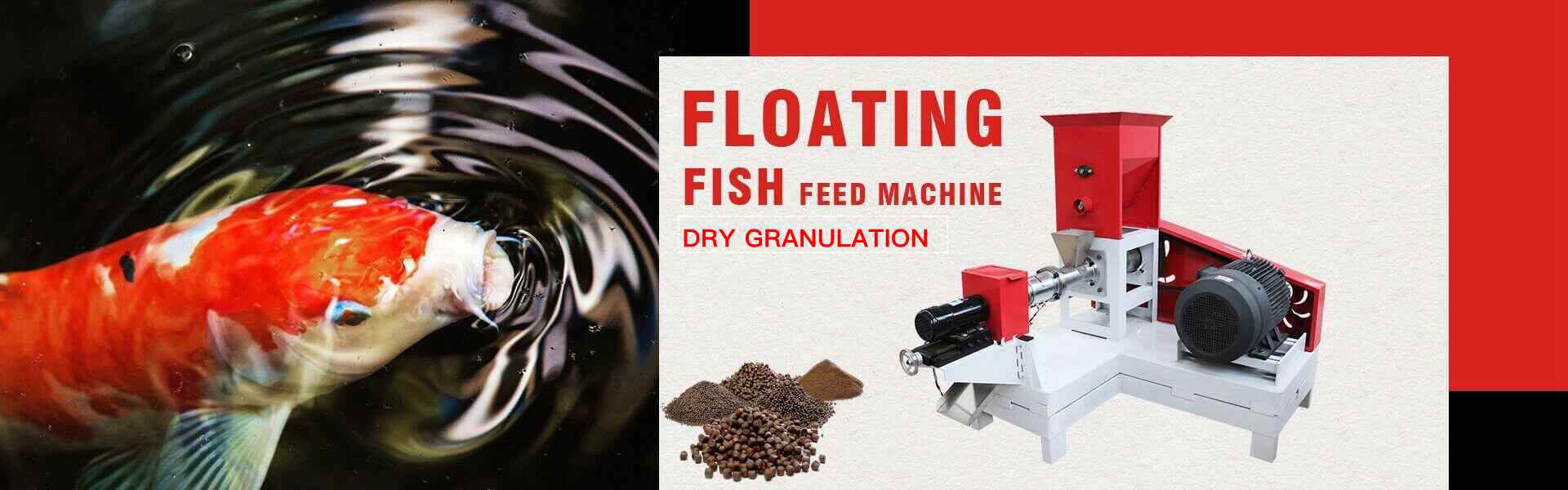

With the benign development needs of low pollution, low waste, high efficiency and high conversion of the global fishery feed, the extruded floating fish food feed pellet is gradually becoming a new type of aquatic feed that is gradually accepted and promoted by the majority of farmers. In recent years, the output of aquafeed has grown rapidly, especially the demand for shrimp and some precious special aquafeeds has increased sharply.

At present, the processing technology and production characteristics of each feed production equipment manufacturer are different, and even the product quality of the same variety produced by the same manufacturer in different batches may fluctuate greatly.

- What are the defects of extruded feed pellet during processing?

- Solutions for defects in extruded fish pellet feed

- 1. The size and length of the feed pellets are uneven

- 2. Too many pores in the feed pellet

- 3. Feed pellets deformation

- 4. The hardness of the feed pellet is not enough

- 5. Poor water resistance and poor viscoelasticity in feed pellets

- 6. The feed pellet incision is irregular and oblique

- High-quality Fish Feed Pellet Display

- 7. Low feed pellet expansion

- 8. The feed pellets do not float

- 9. Feed pellets have different sizes at both ends

- 10. The feed pellets form a double-cut inner concave shape

- 11. Feed pellets with tails

- 12. Peeling on the feed pellet surface

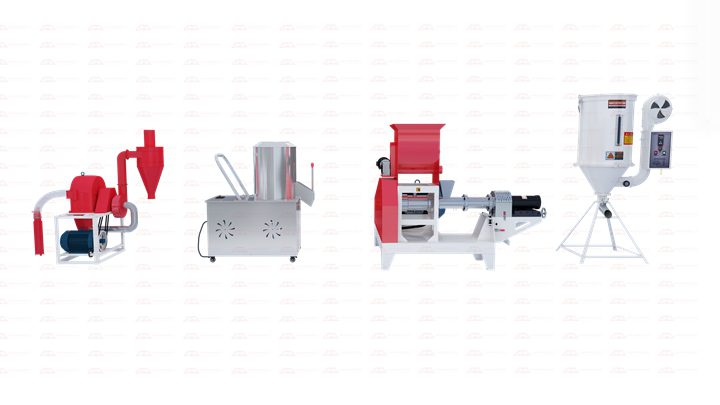

- The good fish feed comes from high-quality fish feed pellet machines

What are the defects of extruded feed pellet during processing?

After years of practical experience in production and continuous communication with customers, we have summarized the following twelve common problems and corresponding solutions for customers’ reference.

- The size and length of the feed pellets are uneven;

- Too many pores in the feed pellet;

- Feed pellets deformation;

- The hardness of the feed pellet is not enough;

- Poor water resistance and poor viscoelasticity in feed pellets;

- The feed pellet incision is irregular and oblique;

- Low feed pellet expansion;

- The feed pellets do not float;

- Feed pellets have different sizes at both ends;

- The feed pellets form a double-cut inner concave shape;

- Feed pellets with tails;

- Peeling on the feed pellet surface;

Solutions for defects in extruded fish pellet feed

After years of constant communication with customers, our floating fish food pellet machine has won the approval and trust of the customers with its excellent performance, advanced technology, and good reputation.

1. The size and length of the feed pellets are uneven

Feed pellets are of different sizes and lengths, which not only affect the appearance of the feed but also affect its palatability and water resistance time inconsistency, resulting in unnecessary waste.

| Reason | Solution |

| Unreasonable opening template | Customized reasonable mold |

| Uneven feeding | Clean and adjust the feeding device |

| Uneven addition of steam or water | Adjust the addition of steam and water level |

| Uneven mixing of materials | Mix multiple times to make the materials evenly mixed |

| Mold blocking | Shut down to clean the mold |

2. Too many pores in the feed pellet

Particles with many pores and rough appearance not only affect the appearance of the feed, but also the feed is easily broken into powder during transportation, causing unnecessary waste. It is not easy to sink during the feeding process, and the floating time is too long.

| Reason | Solution |

| The particle expansion coefficient is too large | Adjust moisture, temperature, and pressure to reduce the expansion coefficient |

| Low starch content in formula | Increase starch content |

| The fineness of the material is coarser | Increase the fineness of crushing |

| Too much moisture during extruding | Reduce moisture content |

| Mold surface is not smooth | Replace mold |

3. Feed pellets deformation

The deformation of the particles may be due to the deformation of the die hole, or due to excessive moisture, which is squeezed and deformed during the conveying process when the die is extruding. Therefore, it is best to use pneumatic conveying for the high-temperature extruded feed that has just been released from the mold, which can not only quickly form a layer of colloidal coating on the surface of the particles, reduce the fragmentation of the particles, but also round the shape of the particles. However, the moisture content of the particles during pneumatic transportation is very heavy, and it needs to be dried as soon as possible.

| Too much moisture during extruding | Reduce moisture content |

| The space of the cover is too small when the mold is extruding | Replace the cover with a large space |

| Excessive extrusion pressure of the host | Reduce the working pressure of the host |

| The cutter speed is too high | Increase the number of blades and reduce the blade speed |

| Excessive expansion rate | Reduce expansion coefficient |

| Die hole deformation | Replace reasonable mold |

4. The hardness of the feed pellet is not enough

Feed hardness is the resistance of feed to deformation caused by external pressure. Insufficient feed hardness will cause deformation of the feed during handling, thereby affecting the appearance of the feed. As a result, the feed is dissolved in the water before it is ingested, or it may be because the water is large, the feed is not easy to store, and it is prone to mildew.

| Reason | Solution |

| There is a large difference in the moisture content inside and outside the particles & the moisture content of the particles is high | Extend the drying time |

| Fast high-temperature drying | Use low-temperature slow drying |

| Insufficient granular starch content | Increase starch content in formula |

5. Poor water resistance and poor viscoelasticity in feed pellets

Water resistance of feed refers to the anti-corrosion ability of feed in water, which is usually expressed by the dissolution rate of feed in water under specified conditions. Poor water tolerance of the feed can cause the feed to dissolve in the water before it is eaten, causing unnecessary waste and contaminating the water. The viscoelasticity is poor, resulting in poor palatability of the feed.

| Reason | Solution |

| Excessive expansion rate | Reduce expansion coefficient |

| Low gluten content in flour | Increase gluten content in flour |

| Insufficient starch content | Increase starch content in the recipe |

| The drying temperature is too high and the surface is deformed | Reduce the drying temperature and prolong the drying time |

6. The feed pellet incision is irregular and oblique

The produced feed should be cut into particles with neat appearance, and irregular and deformed particles will affect the appearance of the feed. Generally, it is caused by the unreasonable adjustment of the incision and the cutter, and it may also be due to the large amount of material.

| Reason | Solution |

| The cutter speed is too slow | Reduce the number of cutter blades and increase the cutter speed |

| The feed amount is too large | Reduce the feed amount |

| The adjustment of the cutter is unreasonable and the cutter is deformed | Adjust the proper cutter and cutter position |

High-quality Fish Feed Pellet Display

The fish feed processed by our floating fish feed pelleting machine has the advantages of high hardness, smooth surface, complete internal ripening, good palatability, etc. It can effectively improve the digestion and absorption of nutrients in the feed pellet. Users can also choose different discharge apertures according to the needs of their own fish groups to obtain the best economic benefits.

7. Low feed pellet expansion

The feed is too hard and the water-dissolving time is too long, which affects its palatability and digestibility. The high content of lipid compounds will reduce swelling. When the fat content is 17-22%, the product will not expand or not expand. The low expansion rate of pellets will cause the feed to float in the water for a short time, and it is easy to sink to the bottom, causing unnecessary waste.

| Reason | Solution |

| The Mould opening rate is too high | Replace reasonable mold |

| The starch content in the material is low | Adjust the formula to increase the starch content |

| The fat content in the material is too high | Adjust the formula to reduce the fat content |

| The moisture is too high or too low when the mold is extruding | Adjust the injection amount of steam and water |

| Low feed volume and low production capacity | Increase feed speed |

| Low pressure during extruding | Increase the extruding pressure |

| Low temperature during extruding | Increase the temperature during extruding |

8. The feed pellets do not float

The particles have the phenomenon of submersion, which may be due to the low expansion coefficient and the material ratio is too heavy. If some granular floating materials appear submerged, firstly, it will cause unnecessary waste, and secondly, it is difficult to observe the situation of fish-eating.

| Reason | Solution |

| Low expansion coefficient | Increase expansion coefficient |

| Excessive proportion of material | Increase the expansion coefficient |

| Low gluten content in flour | Increase gluten content in flour |

| The moisture is too high or too low when the mold is extruding | Adjust the injection amount of steam and water |

| The starch content in the material is low | Adjust the formula to increase the starch content |

| Low temperature during extruding | Increase the temperature during extruding |

9. Feed pellets have different sizes at both ends

One end of the feed pellets is large and the other is small, which affects the appearance of the feed, easily causes the feed to break, increases the pulverization rate, and reduces the palatability.

| Reason | Solution |

| The cutter speed is too slow | Reduce the number of cutter blades and increase the cutter speed |

| The cutter is too tight | Adjust the cutter |

| The effective length of the mold is too long | Replace the mold with a shorter one |

10. The feed pellets form a double-cut inner concave shape

This is usually the case when the double-cut surface of the pellet is concave, the feed is not uniformly extruded, and the ratio of water and steam is unreasonable. Irregular particles not only affect the appearance and quality of the feed, but also lead to too much feed powder and affect its palatability.

| Reason | Solution |

| The moisture content is too low during extruding | Increase the moisture content of the material during extruding |

| Uneven addition of steam or water | Adjust the addition of steam and water level to make them even |

| Low expansion rate | Increase expansion coefficient |

| Unreasonable mold design | Replace mold |

11. Feed pellets with tails

There are many reasons for the tail of the particles, mainly the problem of the cutter. Feed pellets with tails not only affect the appearance and quality of the feed, but also lead to more feed powder.

| Reason | Solution |

| The position of the cutter is not good | Adjust the position of the cutter to make it close to the die surface |

| There is a gap in the mold | Replace the mold |

| There is debris on the cutter | Stop the machine to clean the debris on the cutter |

12. Peeling on the feed pellet surface

The peeling of the surface of the feed is very easy to generate dust during transportation. The peeling of the surface may be related to the lack of moisture in the puffing process, and may also be affected by the mold and cutter in the processing process. It not only affects the appearance and quality of the feed, but also leads to more feed powder. If the water is added too much, the formed material will be too soft and easily deformed. Generally, 25-30% water should be added. Surface peeling also affects the water resistance of the feed.

| Reason | Solution |

| The position of the cutter is unreasonable | Adjust the cutter and replace it with a shaper cutter |

| The moisture content of pellets during extruding is too low | Increase the moisture content during extruding |

| The mold is not smooth | Replace the mold |

| The temperature is too high when the pellets are extruding from the mold | Reduce the temperature during extruding |

The good fish feed comes from high-quality fish feed pellet machines

If you have any questions about fish feed pellets, please feel free to contact us. Our professional sales staff will recommend the most suitable floating fish feed pellet machine for you, with the most affordable price and the most complete service.