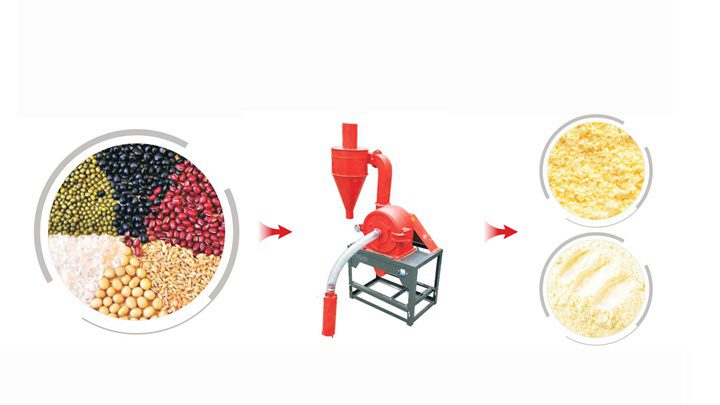

Feed pellet raw material crusher can crush the raw material of feed pellets into powder to meet the needs of the subsequent pelletizing process. The common feed raw material pulverizers include self-priming disc pulverizers, hammer pulverizers, large-scale drop-type comprehensive pulverizers, and two-in-one pulverizing and mixing equipment.

The feed raw material pulverizer is an indispensable piece of equipment in the fish food pellet production line and the poultry feed pellet production line. All feed pellet raw materials need to be pulverized before entering the feed pellet machine for the next step of granulation. The raw materials of feed pellets are mainly soybean, corn, wheat, straw, rice husk, etc. The raw materials used for different feed pellets are also different, and users can choose the appropriate crushing equipment according to their actual needs.

Different kinds of feed pellet raw materials crushing equipment

At present, the raw material pulverizers for fish feed pellets and poultry feed pellets mainly include special self-priming disc pulverizers, hammer pulverizers, and large-scale water drop pulverizers, which are commonly used in pulverizing and mixing equipment on production lines.

1. Self-priming disc crusher

This self-priming disc mill is mainly suitable for crushing grain raw materials, with an output of 200-1000kg/h, and is often used in small family workshop production lines.

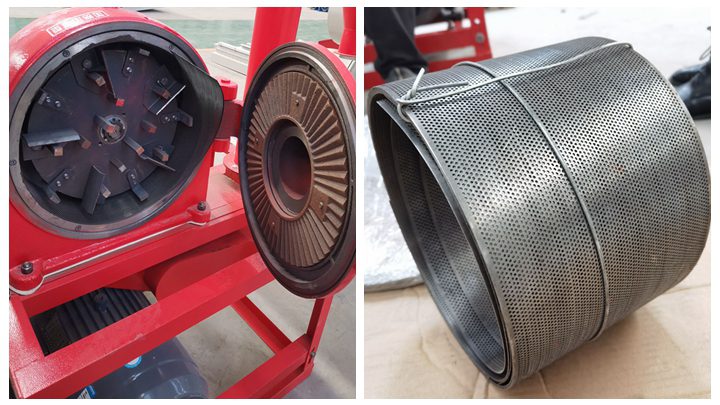

The self-priming disc mill is mainly composed of the mainframe, motor, feeding straw, grinding disc, screen, dust removal device, etc.

The machine body and the grinding disc rotor together form a crushing chamber. The material is sucked into the crushing chamber through the feeding straw, and under the continuous blowing and rolling action of the upper teeth and flat teeth of the grinding disc, it is continuously crushed until the sieve hole meets the fineness requirements.

The pulverized powdery material is discharged through the discharge port under the action of centrifugal force and airflow, and the discharge port is equipped with dust removal equipment.

Parameter of the self-priming disc crusher

| Model | LMFSJ-230 | LMFSJ-350 | LMFSJ-450 |

| Rotor diameter(mm) | 230 | 350 | 450 |

| Capacity(kg/h) | >200 | >800 | >1000 |

| Flat tooth(piece) | 4 | 5 | 6 |

| Square teeth(piece) | 6 | 11 | 12 |

| Voltage(V) | 220 | 380 | 380 |

| Power(kw) | 3 | 11 | 18.5 |

| Dimension(mm) | 700x445x910 | 1140x670x1050 | 1060x1960x1370 |

| Weight(kg) | 40 | 93 | 140 |

2. Hammer crusher

This crusher is not only suitable for grain but also can pulverize some relatively slender straws. The output is 200-1700kg/h, which is suitable for some small production lines.

Parameter of the hammer crusher

| Model | LM9FQ-35 | LM9FQ-36 | LM9FQ-40 | LM9FQ-42 | LM9FQ-50 |

| Rotor diameter(mm) | 300 | 300 | 400 | 500 | 500 |

| Capacity(kg/h) | 80-200 | 150-300 | 200-500 | 300-900 | 800-1700 |

| Hammer(piece) | 24 | 12 | 12 | 16 | 16 |

| Back teeth(piece) | 2 | 2 | 2 | 3 | 3 |

| Voltage(V) | 220 | 380 | 380 | 380 | 380 |

| Power(kw) | 3 | 4 | 7.5 | 11 | 15 |

| Dimension(mm) | 700x570x100 | 750x500x800 | 1100x900x1200 | 1650x820x1200 | 1800x900x1120 |

| Weight(kg) | 90 | 170 | 230 | 260 | 540 |

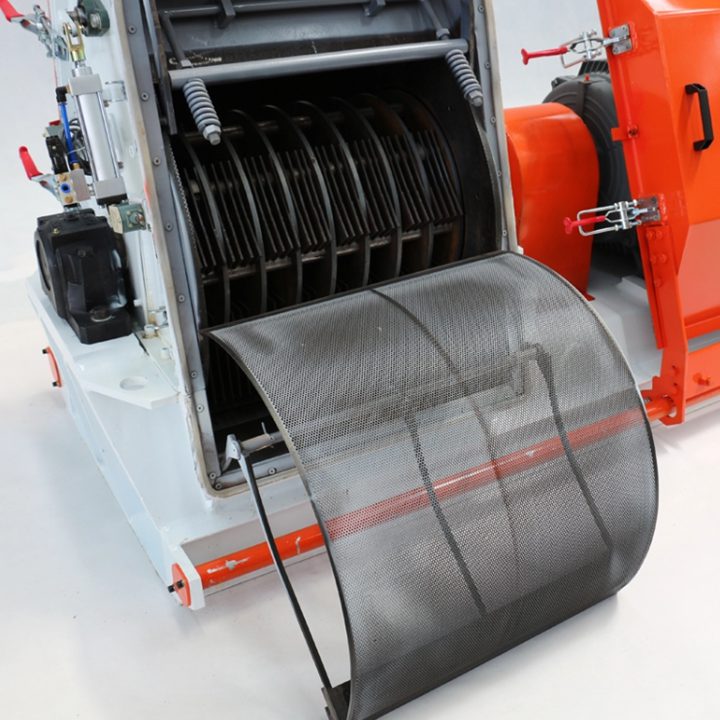

3. Large water-drop type hammer mill

The feed port of this water drop pulverizer is at the top, which can effectively avoid the circulation phenomenon during the pulverization process. The bottom of the crushing chamber is provided with a secondary crushing and striking groove, which can greatly increase the output. The whole machine adopts imported SKF high-quality bearings, which have the advantages of stable performance, safety and reliability, and long service life.

Users can adjust different hammer screen gaps to achieve coarse grinding, fine grinding, and fine grinding so that one machine can be used for multiple purposes.

This large water drop grinder can be used for grinding all raw materials with high efficiency. The output of this grinder can reach a minimum of 1T/H and a maximum of 30T/H, It is suitable for some large feed pellet production lines.

Parameter of the large water-drop type hammer mill

| Model | Power(kw) | Capacity(T) | Voltage(V) |

| LMSFSP-22 | 22 | 1-3 | 380 |

| LMSFSP-55 | 55 | 4-8 | 380 |

| LMSFSP-75 | 75 | 8-12 | 380 |

| LMSFSP-90 | 90 | 12-18 | 380 |

| LMSFSP-110 | 110 | 15-23 | 380 |

| LMSFSP-132 | 132 | 20-25 | 380 |

| LMSFSP-160 | 160 | 25-30 | 380 |

4. Crushing&mixing equipment

The material is fed into the pulverizing chamber uniformly and appropriately from the feeding port. The pulverizing chamber has a hammered piece rotating at a high speed, and the upper body is provided with a tooth plate, and the added material is rapidly under the action of strong striking, tearing and rubbing of the hammer piece. It is pulverized into powder. Due to the centrifugal force and the negative pressure of the lower chamber of the pulverizer, the finely divided material is sucked away by the fan after falling into the lower cavity through the sieve hole and is sent to the centrifugal discharger by the fan or aggregate chamber.

Parameter of the large water-drop type hammer mill

| Model | Crushing Power(kw) | Mixing Power(kw) | Capacity(kg/batch) | Mixing time(min) |

| LM-CM-250 | 7.5 | 2.2 | 250 | 10-15 |

| LM-CM-500 | 11 | 3 | 500 | 10-15 |

| LM-CM-1000 | 11 | 3 | 1000 | 10-15 |