Floating fish feed are pellets that remain on the water’s surface, drawing the fish up to eat. They are typically used for larger underlings, but serve as food for broodfish as well.

Unlike sinking fish feed, floating ones come in handy as you can see the fish eat, and check their consumption. This way, you can control and adjust the amount of fish feed per day, their best feeding times and speed hence minimizing wastage.

Moreover, sinking fish feed contributes to pollution due to the mixture of excess feed, fish faeces and dirty water. You won’t have to worry about such issues with floating fish feed. That means more healthy fish!

Raw Materials and Ingredient Selection

For the fish pellets to float it is important to ensure that they are low bulk viscosity, low humidity, water stability and their air sacs are extruded in order to increase fish digestibility.

To make the floating fish feed pellet, the raw materials should include, fish mess, wheat meal, yeast powder, mineral and vitamin premix, soybean mess, cottonseed mess, peanut mess and rapeseed mess as some of the main ingredients.

Feed Manufacturing Process

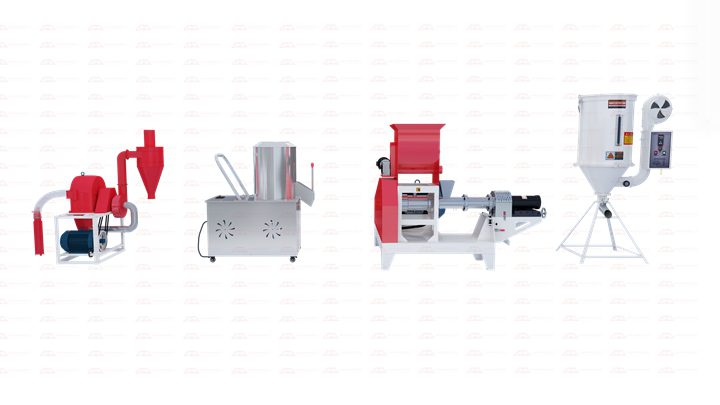

For production more so the extrusion process, work with quality gear like machines from LIMA Feed, where the pellets are made evenly and properly stirred to include all ingredients in every pellet.

Additionally, depending on the shape you like, the machine allows you to make different feed sizes for your fish when you use their new generation fish food pellet machine.

Feed milling is vital in animal feed production and the rule of thumb is selecting an experienced feed mill manufacturer so that your feed is nutritionally balanced.

Grinding and Mixing

After buying the raw materials needed, and storing them in silos or bins with proper temperature and humidity, grind them using the LIMA Feed Machine into smaller particles.

For aquatic animals that eat little and have a short digestive tract hence bad digestibility, secondary grinding is paramount. This is through re-grinding, breaking the fish feed into more fine particles.

Conditioning

Once done, depending on the fish you are feeding, you should ensure that the grinded particles form a uniform mixture that has all essential nutrients before adding steam and head to the mixture, a process known as conditioning.

After that, the mixture can be processed using pellet mills or extruders. The latter can be powered by an electric motor or diesel engine and are very suitable for small and medium fish farms.

Coating

Before or after pelletizing, you can choose to either coat the feed with both animal fats and plant oils. However, the volume of addition of the animal fats and plant oils should not affect the solidness of the pellets.

Packaging and Storage

After the process is completed, the feed pellets need to be cooled and dried to remove excess moisture before you packing. However, it is important to note that while packing, you must use an air tight bag to prevent oxidation and store the feed safely to avoid contamination.

Final Thoughts

After buying the floating fish feed pellet machine, you can be able to know and judge the quality of the pellets you make by how they look, smell, twist, foam and chew.

The pellets colour depends on the number of raw materials you used, if it has a unique fragrance, and does not break when twisted with your fingers but then again not too hard.

Also, if you put the feed in water, it should have completely dispersed after 3-5 minutes and a simple taste-test can help identify whether the pellet is hard or has scent or not.