The floating fish feed pellet production line generally includes the following process: grinding, mixing, pelleting, cooling, screening, drying and packing. The material will first be pulverized into powder by a pulverizer, and then different raw materials are added according to different formulas for mixing, and then the stirred raw materials are put into the floating fish feed pelleting machine for granulation, after the produced fish feed pellets are cooled and dried, it can be packaged.

Our floating fish food pellet production line has a variety of configurations to choose from, including domestic small units with a typical output of 50-200kg/h, commercial production lines with 200-500kg/h, and the ultra-large factory production line with 2-5T/h. At present, the factory has more than 50 kinds of floating fish food pellet production line solutions. Generally, we will customize large-scale production lines according to customer needs. We can also arrange for our technicians to go to the customer’s factory to assist in installation and use. As a professional feed production equipment manufacturer, all equipment on the entire production line can be customized to meet the needs of customers to the greatest extent. Welcome customers to come to consult and visit the factory.

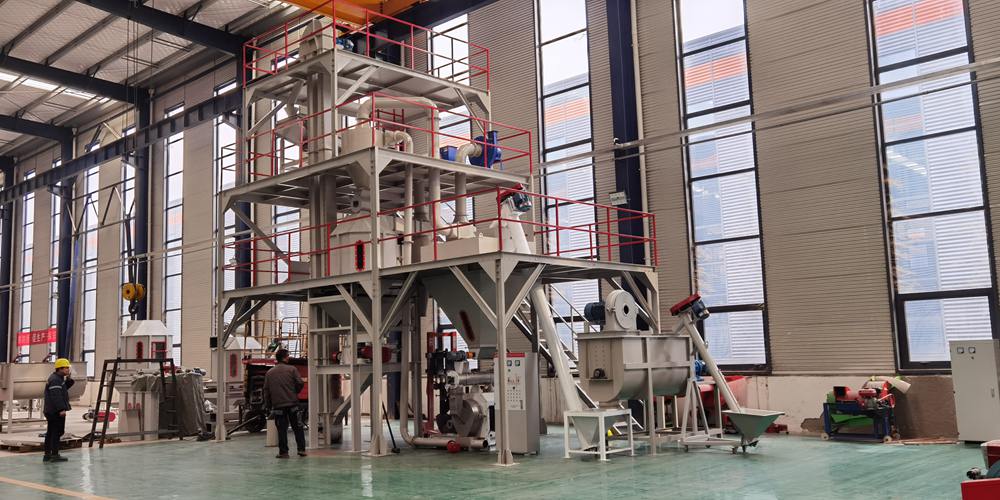

- Display of the floating fish feed production line in our factory

- The production process of the floating fish feed pellet

- Video display of the floating fish feed pellet production line

- Main equipment in the floating fish feed pellet production line

- Display of the different outputs of floating fish feed pellet production line

- Customer projects display

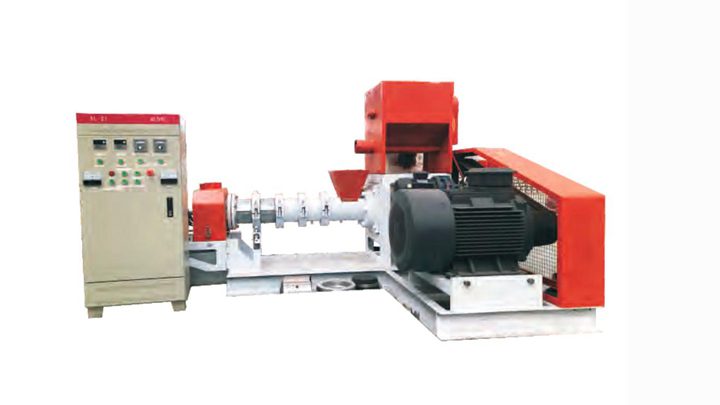

Display of the floating fish feed production line in our factory

Lima machinery has been in the floating fish feed pellet industry for nearly ten years, focusing on the production of fish food extruded pellet machines. In addition, our factory has dozens of different fish feed pellet production line solutions for customers to choose from.

The production process of the floating fish feed pellet

The main steps of the floating fish food pellet production line include crushing and mixing of raw materials, followed by pelleting, cooling and drying treatment for the pellet, and finally packaging.

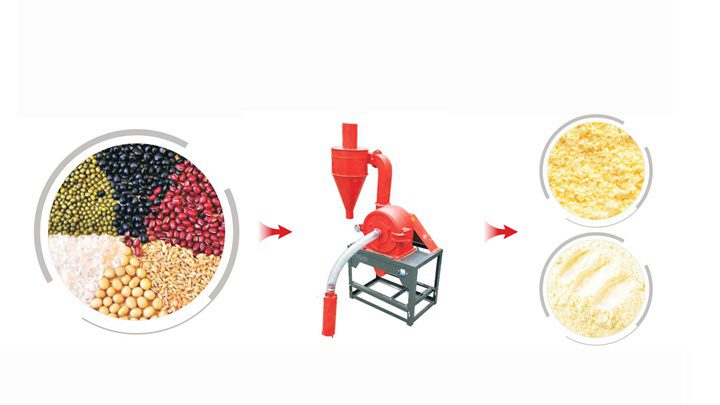

- Crushing: This step is mainly to crush some grain raw materials (corn, soybean, wheat, etc.) into powder, which is convenient for subsequent granulation processing.

- Mixing: The crushed raw materials need to be mixed according to different formulas, and some nutrients such as bone meal will also be added during this process.

- Pelleting: The processed raw material is ready for pelleting. The granulation of floating fish food granules has two methods: dry method and wet method. Customers can choose according to their own specific needs for fish food pellets.

- Cooling&Drying: The fish food pellets after being granulated by the floating fish food pelleting machine need to be cooled and dried to obtain the final product.

- Packaging: The final product is packaged in an automatic weighing baler.

Video display of the floating fish feed pellet production line

Main equipment in the floating fish feed pellet production line

In the production process of floating fish food pellets, the main equipment used includes the grain crusher, powder mixer, fish feed pellet machine, cooling equipment, drying equipment, automatic weighing and packaging machine and some ancillary equipment.

In the production process of fish food pellets, the machines used in different stages are also different according to the requirements of output, production efficiency, fish food quality and so on.

1. Raw materials crusher

There are three kinds of raw materials crushers for fish feed pellet: Self-priming disc crusher, hammer crusher, and large water-drop type hammer mill.

1. Self-priming disc crusher: This crusher is more suitable for the grains, the output is 200-1000kg/h, and it is suitable for some small unit production lines.

2. Hammer crusher: This crusher is not only suitable for grain but also can pulverize some relatively slender straws. The output is 200-1700kg/h, which is suitable for some small production lines.

3. Large water-drop type hammer mill: This hammer mill can crush all kinds of raw materials, with a minimum output of 1T/H and a maximum of 30T/H. It is suitable for some large production lines.

2. Mixing machine

There are also three types of mixers suitable for different outputs, namely small vertical mixer, horizontal ribbon mixer, and double-shaft paddle mixer.

1. Vertical mixer: The inside of this vertical mixer is a continuously rotating stirring shaft, and the output is 15-50kg/batch, which is suitable for small unit production lines.

2. Horizontal ribbon mixer: The output of the horizontal mixer is large, and each batch can handle 150-1000kg, which is suitable for small production lines.

3. Double-shaft paddle mixer: This double shaft paddle mixer is widely used in various industries, with an output of 250-3000KG/BATCH, suitable for large production lines.

3.Floating fish feed pelleting machine

According to the different pelleting processes, the fish food pellet machine is divided into two different production methods: dry way and wet way. Both fish pellet machines are capable of producing high-quality floating fish pellets.

4. Cooling and drying equipment

5. Automatic weighing and packing machine

The quantitative packing machine is a combination of computer weighing and packaging machines, with the function of automatic feeding, automatic weighing, automatic zero-cleaning, automatic accumulation, error alarming, and so on. Widely used in the packing of rice, wheat, corn, sugar, salt, washing powder, and other particles.

6. Auxiliary equipment

In the feed pellet production line, there are many other auxiliary equipments, such as seasoning machines that can make floating fish food pellets more flavorful, screening machines that facilitate the screening of different particle sizes, various conveying equipment, etc.

1. Seasoning equipment

The machine for flavoring various foods and feeds, during Continuous processing machine can mix and coating the liquid, powder, oil .make outlook is smoothly and uniformity, improve the feed taste and quality.

2. Screening machine

3. Conveying equipment

Display of the different outputs of floating fish feed pellet production line

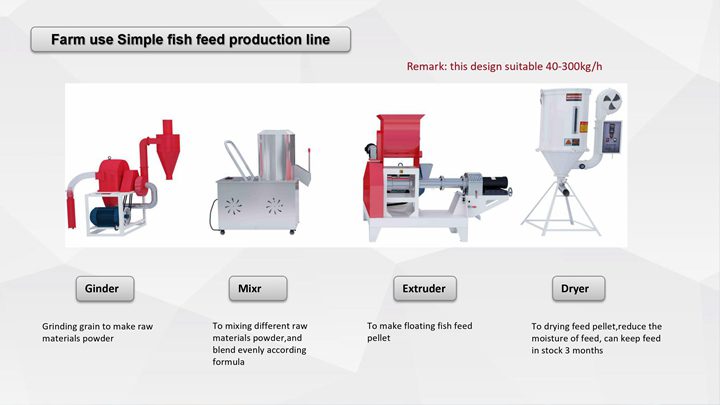

1. Farm-use simple fish feed production line 40-300kg/h

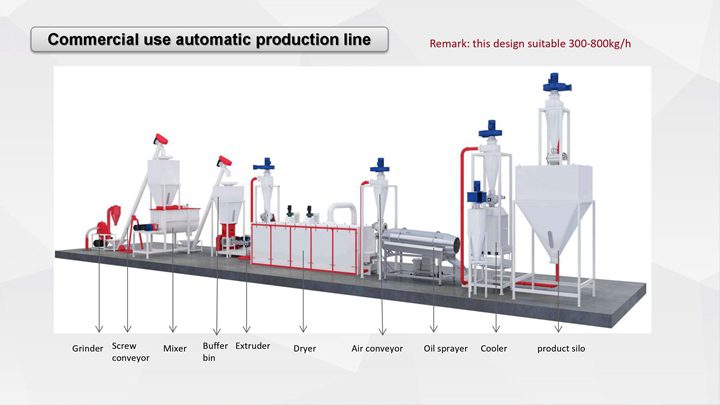

2. Commercial use automatic production line 300-800kg/h

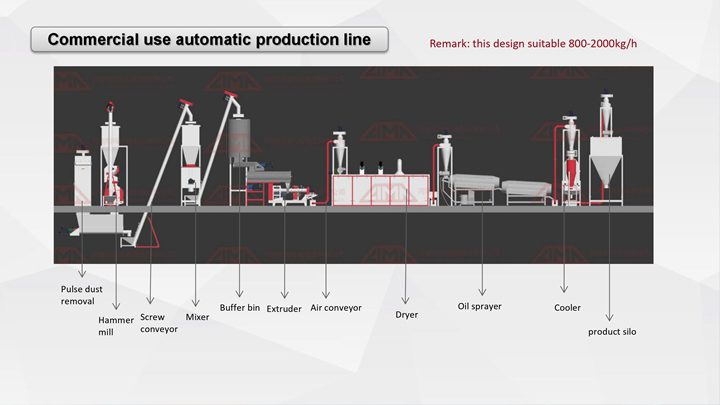

3. Commercial use automatic production line 800-2000kg/h

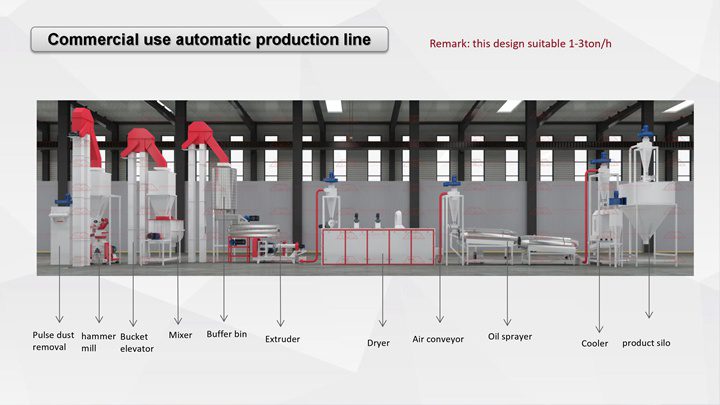

4. Commercial use automatic production line 1-3T/h

Customer projects display