Extruded Fish Feed Machine | Floating Fish Feed Pellet Machine By Dry Way

The fish feed pelleting machine is feed processing equipment that uses corn, soybeans, and other grains as raw materials to produce floating fish feed pellets. The fish feed processed by our floating fish feed pelleting machine has the advantages of high hardness, smooth surface, complete internal ripening, good palatability, etc. It can effectively improve the digestion and absorption of nutrients in the feed pellet. Users can also choose different discharge apertures according to the needs of their own fish groups to obtain the best economic benefits.

Over the years, our products have been exported all over the world and have been well received by our customers, especially those in Africa and Asia. After continuous communication with our customers, our R&D team has developed a new generation of fish food pelleting machines. This series of fish food pelleting equipment adopts a new structural design, which has the advantages of refined structure, wide adaptability, and low noise, which can meet the needs of different customers.

- Extruded Fish Feed Machine | Floating Fish Feed Pellet Machine By Dry Way

- 1. Display of the floating fish feed machine

- 2. The parameters of the floating fish feed machine

- 3. Preparation before shipping to customers

- 4. Customer feedback on the floating fish feed-making machine

- 5. Video display of the floating fish feed machine

- 6. The structure of the floating fish feed extruder

- 7. The working principle of the dry way floating fish feed making machine

- 8. The raw materials for floating fish feed pellet

- 9. The advantages of the floating fish feed machine

- 10. Which is better floating or sinking fish food?

- 11. Features of extruded floating fish feed making machine

- 12. Tips on How to use floating fish feed extruder

- 13. Common problems and solutions of the floating fish feed making machine

- 14. How to judge the quality of floating fish feed?

- 15. Fish feed pellet formula in the different fish growth stages

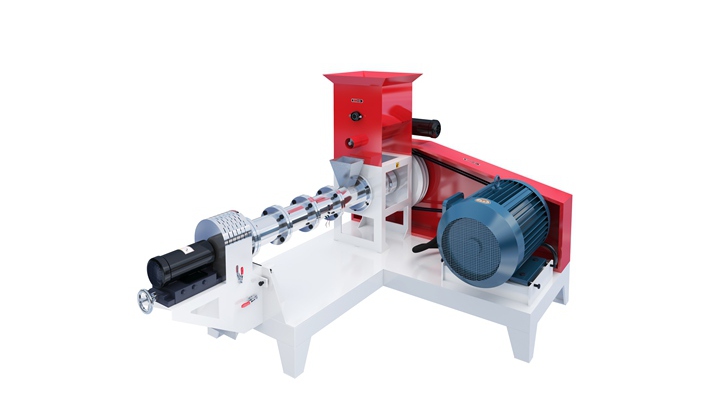

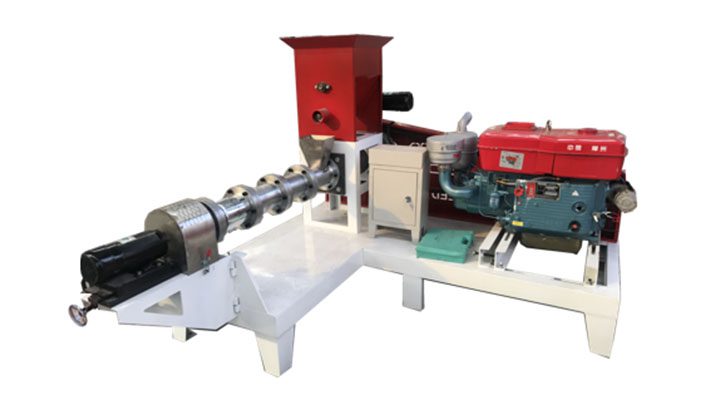

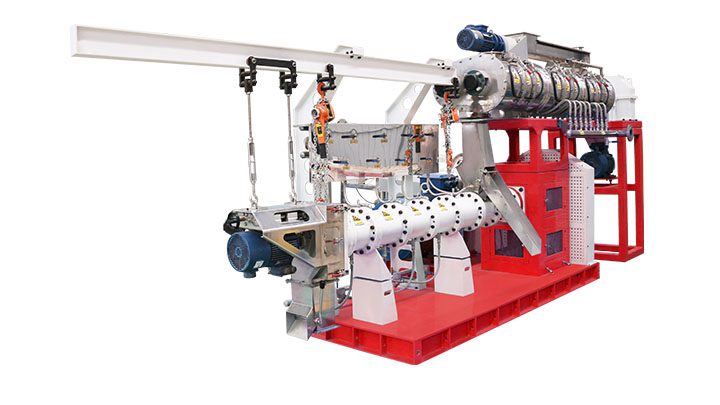

1. Display of the floating fish feed machine

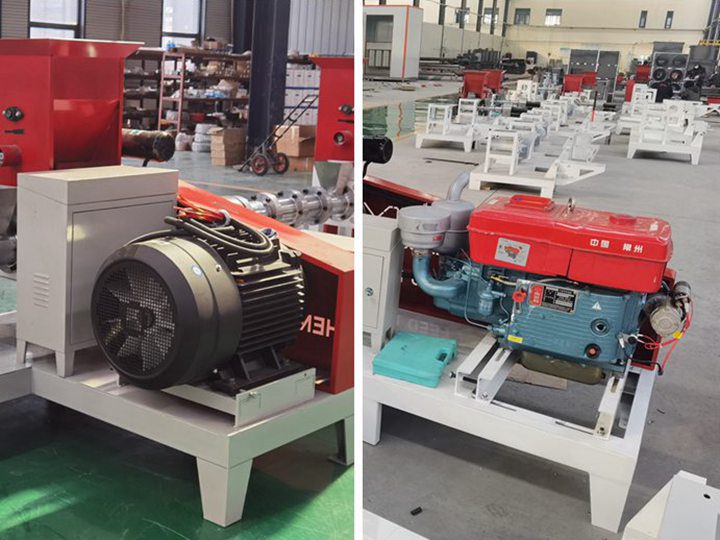

There are various models of our fish food pellet machine, from 40kg/h to 3-4 tons per hour. As for 40kg/h to 300kg/h fish feed extruder, which can be powered by an electric motor or a diesel engine. This machine is very suitable for small and medium fish farms. We provide different molds for making different sizes of fish feed, from 0.8mm to 12mm.

Our factory has a very sufficient inventory of single machines and is equipped with several production lines with different outputs. Customers are welcome to visit the factory and test the performance of the machine on the spot.

2. The parameters of the floating fish feed machine

| Model | Capacity (kg/h) | Main power (kw) | Feeder power (kw) | Screw Diameter (mm) | Cutter power (kw) | Dimension(mm) | Weight (kg) |

| LM-40 | 40-60 | 5.5 | 0.4 | Φ40 | 0.4 | 1400*1030*1200 | 240 |

| LM-50 | 80-100 | 11 | 0.4 | Φ50 | 0.4 | 1470*1100*1250 | 340 |

| LM-60 | 160-180 | 15 | 0.4 | Φ60 | 0.4 | 1470*1100*1250 | 450 |

| LM-70 | 180-200 | 18.5 | 0.4 | Φ70 | 0.4 | 1650*1400*1300 | 480 |

| LM-80 | 200-300 | 22 | 0.6 | Φ80 | 0.6 | 1800*1450*1300 | 760 |

| LM-90 | 380-400 | 37 | 0.6 | Φ90 | 0.6 | 2100*1450*1350 | 950 |

| LM-120 | 500-600 | 55 | 1.5 | Φ120 | 1.1 | 2440*2020*1650 | 1795 |

| LM-135 | 750-800 | 75 | 1.5 | Φ135 | 2.2 | 2470*2060*1650 | 2264 |

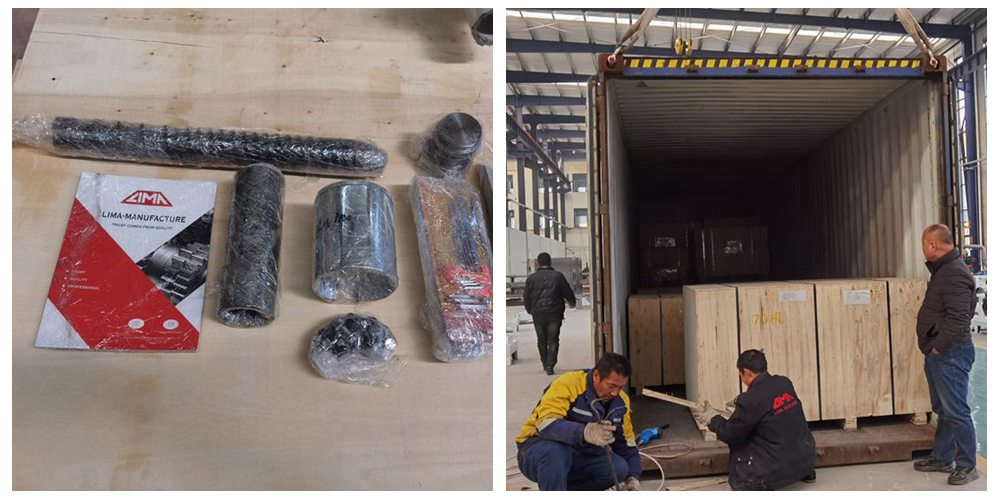

3. Preparation before shipping to customers

All machines are tested and adjusted before being sent to customers to ensure that customers receive the machines and can use them directly.

All goods will be wrapped with plastic film to prevent moisture erosion during shipping, and then fully packaged in wooden boxes.

The machine is also sent to the customer with the machine instruction manual, wearing parts accessories, and a set of common mechanical maintenance tools.

4. Customer feedback on the floating fish feed-making machine

Lima Feed Machinery has been serving customers with advanced technology and reliable performance for more than 20 years. Our products are exported to Africa and have many customers in Nigeria, Kenya, Ghana, and other countries, and have received consistent recognition from customers in Africa.

Nigeria is our largest market, we have a lot of local customers, if you need to visit our fish pellet equipment, we can provide you with contact information. In addition, the production of fish food pellets in Nigeria is also very promising, and good economic benefits can be obtained whether it is used by itself or sold.

5. Video display of the floating fish feed machine

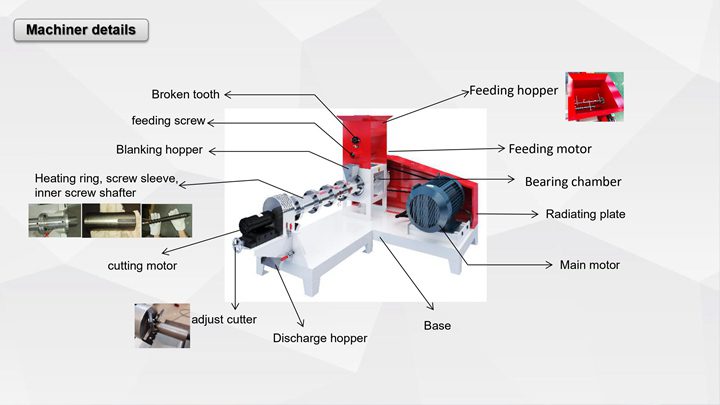

6. The structure of the floating fish feed extruder

Our new generation fish food pellet machine is mainly composed of three parts: feeding system, pelletizing system, and discharging system.

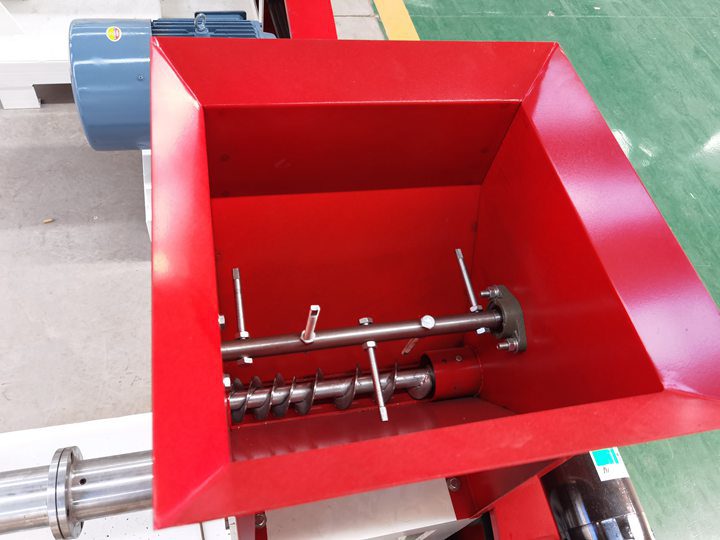

1. Feeding system: After the material is crushed, it first enters the storage bin above. The storage bin is designed with a large opening to facilitate feeding, and there is a spiral agitator inside, which evenly transports the material to the feed port of the granulation system below. The feeding system can ensure that the material can enter the pelleting system evenly, and ensure the quality of the finished feed.

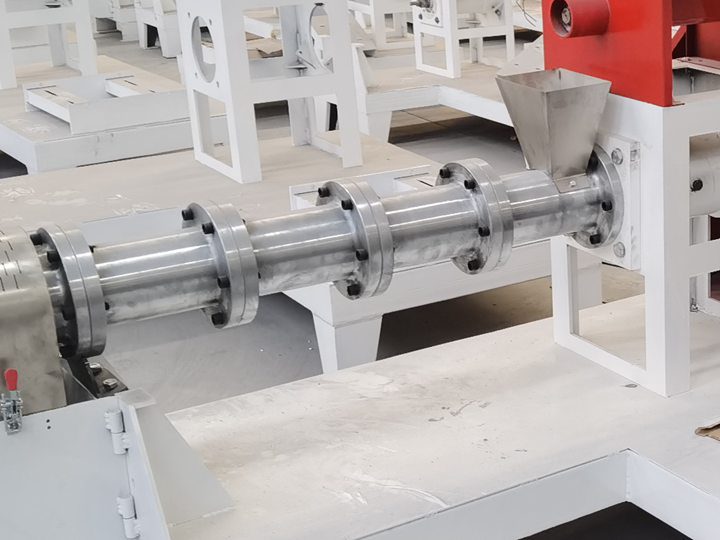

2. Pelletizing system: The material enters into the lower granulation system after being evenly stirred by the feeding system. The material is under the condition of high temperature and high pressure in the advancing screw, and gradually forms a granular feed, which is finally extruded from the top die by the screw. The user can add an electric heating sheet outside the screw to assist with heating,

3. Discharging system: After the material is extruded through the die, it is cut by the final rotary cutter, then obtain the finished feed. The user can adjust the rotation speed of the blade and the distance from the blade to the die outlet to obtain different feed lengths, and adjust the aperture and shape of the discharge die to obtain different feed sizes.

4. Power system: Our fish pellet machine can use two different power modes, motor and diesel engine, and can also be modified into a hybrid power mode according to customer needs.

The main motor is mainly used to control the screw in the pelletizing system. The high-speed rotating motor makes the extrusion screw move forward smoothly and continuously through the deceleration motor, then it will form a high temperature and high-pressure condition.

In addition, the whole machine is equipped with two small motors, which are the feeding motor that controls the spiral stirring feeder in the feeding system and the cutter motor that controls the rotation of the blade when discharging.

7. The working principle of the dry way floating fish feed making machine

The crushed material enters the screw extrusion cavity after uniform stirring. Under the action of the main motor, a high temperature and high-pressure condition are formed in the cavity (an electric heating sheet can be added outside the cavity for auxiliary heating). At the same time, the material is in the cavity also accompanied by violent extrusion, stirring and friction in the process of moving forward. Under various actions, the temperature of the material in the cavity rises sharply, the starch in the material is gelatinized, and the whole material becomes a melted plastic colloid.

When the material is extruded from the mold, the moisture in the material quickly turns into steam, the volume of the formed feed expands rapidly, and the further evaporation of the water vapor reduces the moisture content of the feed. At the same time, the temperature of the feed drops rapidly, and it is finally cut by the rotary cutter and cooled.

8. The raw materials for floating fish feed pellet

Fish feed floats on the water face due to various reasons like low bulk viscosity, air sacs in extruded feed, low humidity, buoyancy – water stability & other extrusion properties nominated as floating fish feed.

The raw materials of floating fish feed are wide and colorful, substantially including fish mess, wheat meal, yeast powder, mineral and vitamin premix, soybean mess, cottonseed mess, peanut mess and rapeseed mess, etc. still, without proper and scientific expression, floating fish feed may show some blights like deficient nutrition, high feed measure, and low feed Application rate. Thus, it’s essential to choose a formula with good stability, low feed measure, and high feed application rate, and to master the production process overall.

9. The advantages of the floating fish feed machine

- The granulation equipment has a simple structure, small footprint, low noise, and long service life.

- The machine adopts a variety of powerful methods to meet the needs of different customers,

- The produced feed pellets have a smooth surface and internal ripening, which not only has good palatability but also improves the digestion and absorption of internal nutrients by fish.

- The high temperature and high-pressure environment during the formation of feed pellets can effectively kill bacteria, parasite eggs, pathogenic microorganisms, etc. in the material, and avoid various digestive system diseases.

- A variety of mold sizes and shapes are available to suit different species and sizes of fish.

10. Which is better floating or sinking fish food?

Floating Feed: This type of feed floats on water. These feeds go through the extrusion process during processing, so the purchase and manufacturing costs are advanced.

Sinking Feed: This is just contrary to the former. It’ll sink directly into the water. They’re more economical.

There are both pros and cons to the two types of pellets. Still, the use of floating pellets provides further advantages compared to sinking ones.

11. Features of extruded floating fish feed making machine

- The extruded aquatic feed can be suspended on the water surface for a long time, it helps farmers to carry out scientific feeding management.

- The utilization rate of extruded floating extruded material is higher.

- The impact of extruded fish feed on water quality is low.

- The floating fish feed pellet has a longer shelf life and is convenient for storage and transportation.

- The extruded feed pellet is very stable in water, it can avoid spoilage of feed pellet.

- The extruded feed can effectively kill harmful bacteria which can prevent the unclean feed from causing various digestive tract diseases.

12. Tips on How to use floating fish feed extruder

- When the fingerlings are stocked, when the water temperature is low, the growth is slow, and the size is small, the particle diameter of the feed should be controlled at about 2mm; when the temperature rises and the growth of fingerlings are accelerated, the medium-term feed particle diameter should be 3-3.5mm, and later in 4-4.5mm. Therefore, when using the fish feed pellet machine to process fish pellet feed, the size of the feed pellet should be adjusted according to the type of fish and different growth stages to achieve the best feeding effect.

- Because the fish has no stomach, the feed stays in the intestinal tract for a short time, and the digestion and utilization rate is not high; so when feeding the feed, it should be fed several times, and each feeding should be a little less; Improve feed utilization.

- During the use of the feed pellet machine, the preventive medicines, and raw materials can be mixed and pelleted according to the current epidemic diseases and fish disease occurrence seasons, which can effectively prevent fish diseases and improve the survival rate of aquatic products.

13. Common problems and solutions of the floating fish feed making machine

In the production process of feed pellets, different problems may occur. We have summarized the following common problems and summarized the reasons and corresponding solutions for reference.

| Problems | Solutions |

| With a tail | There should no gap between cutter and mold Add cutter speed slowly by slowly |

| Too longer | Add cutter speed slowly by slowly |

| Too short | Reduce cutter speed slowly by slowly |

| Surface not smooth | The starch content is less |

| The surface is spiny | The raw material is too dry, add water to the formula |

| Not floating | The starch content is too low and the oil content is too high |

| Feed can’t come out | Check whether the mold is blocked or the machine is assembled correctly |

You can know more details about the solutions from this article: Common problems and solutions in the production of floating fish feed pellets.

14. How to judge the quality of floating fish feed?

Click here to know more: How to judge the quality of fish feed pellets?

In recent years, with the increasing popularity of high-yield fish farming, the use of full-price pellets for fish in fishery production has become very common. However, due to the many feed brands on the market, and there are great differences in quality and grade, the majority of fish farming The user cannot judge the quality of the fish feed. This article introduces a simple method to judge the quality of fish feed using the senses. Namely:’One look, two smells, three twists, four foams, five chews’ for your reference when choosing pellet feed.

15. Fish feed pellet formula in the different fish growth stages

In different growth stages of fish, there will be certain differences in the ratio of nutrients required by fish, which is to enable fish to grow healthier and faster. If the ratio of nutrients is not appropriate, it may lead to fish malnutrition, slow growth, and even serious consequences of fish diseases.

- Small fish recipe: Protein content: 34-36%

Ingredients: Corn meal: 30%, Fish meal: 20%, Rice bran: 5%, Soybean meal: 30%, Bone meal: 2%, Wheat bran meal: 13% - Medium Fish Recipe: Protein Content: 30%

Ingredients: Corn Meal: 30%, Fish Meal: 15%, Rice Bran: 10%, Soybean Meal: 25%, Bone Meal: 2%, Wheat bran meal: 18% - Big Fish Formula: Protein Content: 28%

Ingredients: Corn meal: 35%, Fish meal: 15%, Rice bran: 10%, Soybean meal: 20%, Bone meal: 2%, Wheat bran meal: 18%

Click here to know more: How to design a suitable fish feed pellet formula in the different fish growth stages?

Therefore, we need to choose the appropriate fish food formula according to the type of fish and different growth stages, so as to ensure the comprehensive and balanced nutrition required by the fish, maximize the use of the nutritional value in the feed, and at the same time comply with economic principles and minimize the cost.