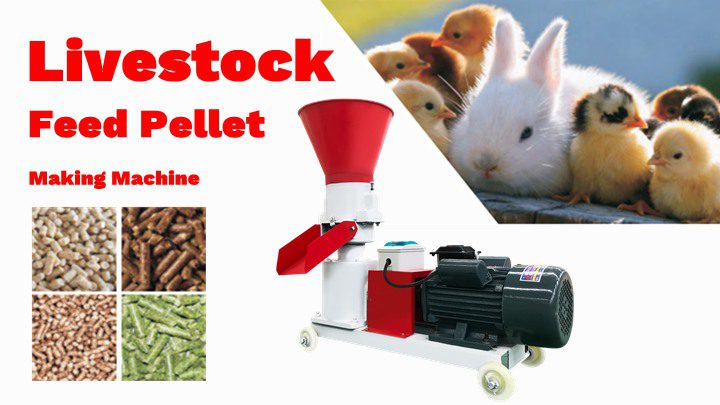

Flat die livestock pellet machine is a kind of animal feed-making equipment, it uses the soybean, corn, soybean meal, and other grain materials as the materials to make the poultry feed pellets. The granular feed processed by this machine has a smooth surface and moderate hardness. This machine is mainly suitable for the processing of feed pellets for ducks, chickens, rabbits, pigs, cattle, sheep, etc. The particle size diameter during granulation can be customized according to the needs of different growth periods of farmed animals. The machine has a simple structure, low noise, and wide applicability, which is ideal equipment for the production of livestock and poultry feed pellets.

- Factory display of the livestock feed pellet machine

- Parameter of the poultry pelleting machine

- Structure of the livestock feed pellet machine

- The principle of the flat die feed pellet making machine

- The advantages of flat die poultry feed pellet mill

- The raw materials and applications of the livestock feed pellets

- Tips during the pelleting process

Factory display of the livestock feed pellet machine

Parameter of the poultry pelleting machine

| Model (electric) | Capacity (kg/h) | Main power (kw) | pellet size (mm) | Machine size (mm) | weight (kg) |

| LM120 | 60-100 | 3 | 60-100 | 750*310*620 | 80 |

| LM150 | 90-120 | 4 | 44965 | 770*340*680 | 95 |

| LM210 | 200-300 | 7.5 | 44965 | 1000*430*950 | 190 |

| LM230 | 300-400 | 11 | 44965 | 1150*500*970 | 290 |

| LM260 | 400-600 | 15 | 44965 | 1200*500*1030 | 330 |

| LM300 | 600-800 | 22 | 44965 | 1320*530*1070 | 440 |

| LM400 | 800-1000 | 30 | 44965 | 1450*620*1180 | 600 |

Structure of the livestock feed pellet machine

The flat die pellet machine is mainly composed of a power system, a feeding hopper, a pressing roller, a die orifice plate, and a discharge port. The power system can be either a motor or a diesel engine. The power system needs to be equipped with a gear motor so that the machine can obtain more Large torque to get more powerful power for pelletizing. The feeding hopper at the entrance adopts a large opening design to facilitate feeding.

Press rollers generally have two-roller, three-roller, and four-roller models according to the demand of output. The grinding disc is the part of the material forming, which is made of high-quality alloy material, and the size of the die hole on the grinding disc can also be changed according to the needs of customers.

The principle of the flat die feed pellet making machine

The working principle of the flat die granulator is very simple. The motor or diesel engine drives the roller to rotate continuously. After the raw material enters the feeding hopper, it is pressed into the lower grinding disc under the action of its own gravity and the continuously rotating pressing roller. The cylindrical material It is extruded from under the die hole and cut into feed pellets by the rotating blade.

The advantages of flat die poultry feed pellet mill

- Animal feed pellets are comprehensive in nutrition, animals are not easy to picky eaters, and the separation of nutrients is reduced.

- Pelletized feed is conducive to full digestion, absorption and utilization of livestock and poultry, and improves the digestibility of feed.

- After high-temperature sterilization, reduce the possibility of feeding mildew and insects and improve the palatability of feed.

- Strong stability, not easy to collapse in the water, not easy to pollute the water body.

- Small size, not easy to disperse, not easy to be damp, easy to store and transport in bulk.

The raw materials and applications of the livestock feed pellets

The raw materials used by the flat die pellet machine are generally soybean, corn, soybean meal, and other materials. Generally speaking, different types and growth stages of livestock need different feed raw materials.

This flat die pellet machine is mainly suitable for medium-and small-scale farming professional households and other processing of various livestock and poultry and aquatic Pellet feed can reduce the cost of aquaculture. It can be used for raising rabbits, chickens, ducks, geese, fish, pigs, cattle, sheep, aquatic products, and so on.

Tips during the pelleting process

The moisture content in the material has a great influence on the pressurization effect of the flat model. The study found that the moisture in the mixed material should be controlled between 8% and 10%. Rough surface, low strength,

If the output is low, the load of the main machine will be large; if the moisture content is too high, the particles will be easily formed and extruded into agglomerates.