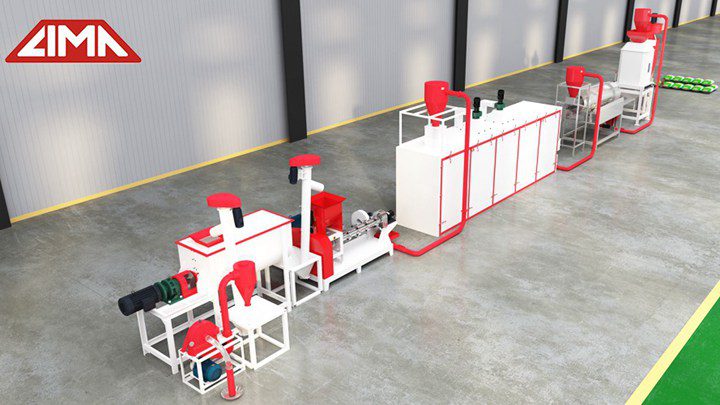

The automatic floating fish pellet production line is generally used in some large-scale production lines, which can effectively improve production efficiency, reduce production costs, and stabilize and improve product quality. The fully automatic floating fish pellet production line can effectively help the factory to realize the modernization of production and has good economic benefits.

In the fully automatic floating fish pellet production line, various conveying devices are used to connect the various systems. The entire production line is reasonably configured and can be customized according to customer needs.

Lima machinery has been in the fish feed pellet industry for nearly ten years, our factory has dozens of different floating fish feed pellet production line solutions for customers to choose from. After continuous communication with customers, our feed pellet machine has received praise from customers, especially those in Africa and South Asia. If you have any questions, please feel free to contact us, our professional technicians are more than happy to help you.

Automatic production line machine introduction

Fish feed hammer mill-Fish Feed Mixer→Fish Feed Feeder→Operating Platform→Fish Feed Extruder→High Pressure Air Conveyor→Fish Feed Oven→Elevator→Seasoning Line→Cooling Conveyor

Machines are included in the fully automatic production line

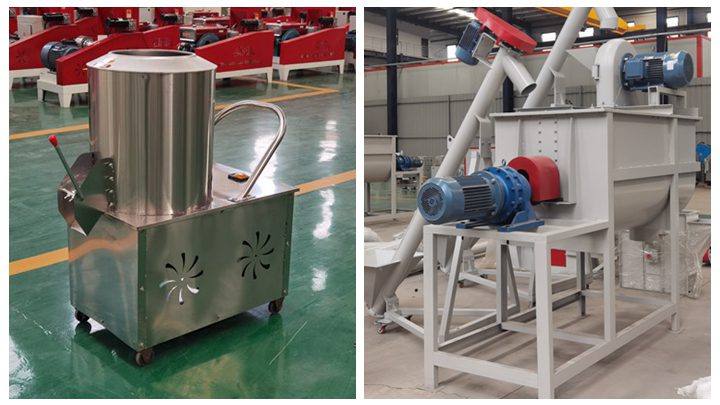

1. Crushing unit

The crushing unit is used for crushing and crushing the raw materials of fish feed. By replacing the screen of the crusher, it can achieve the purpose of producing the required products. Large-scale fish feed production lines require a large number of raw materials, so generally, the raw materials are purchased and crushed by themselves to save costs.

Fish feed raw material pulverizers are generally divided into two types: ordinary pulverizer single machine and pulse dust removal pulverizing unit. The price of a single machine of ordinary pulverizers is reasonable, and a separate pulverizing workshop needs to be prepared for pulverizing raw materials. The pulse dedusting pulverizer adopts pulse dedusting equipment, which can effectively avoid dust, so it can be placed at will according to the cycloid of the fish feed production line during work.

2. Mixer

It is used for pre-mixing, mixing powder, and other functions before fish feed production. Small fish feed production lines use vertical powder mixers, and large fish feed production equipment generally uses horizontal mixers. As the main equipment for mixing raw materials, the mixer is generally made of stainless steel for the barrel wall and the teeth. It can effectively avoid rust and other phenomena caused by the erosion of equipment by materials and water.

3. Feeder

It is used to transport the mixed fish feed raw materials into the feeder or storage bin. Small fish feed production lines generally use screw feeders, and large fish feed production machines use bucket lift feeders.

4. Operation platform + storage bin

4. Operation platform + storage bin: Due to the large output of large-scale fish feed production lines, sufficient raw materials must be prepared before each production to supply production needs. Therefore, general large-scale fish feed production lines use silos to temporarily store mixed raw materials. The wall of the storage bin is made of stainless steel, and vibration motors are installed on both sides of the wall. By adjusting the amplitude of the vibration motor, the problem of raw materials remaining in the storage bin can be effectively avoided. The operating platform allows workers to observe the storage of raw materials in the silo and the working conditions of the equipment on the platform at any time.

5. Extruding machine

The extruding main machine is the main production equipment for the production of fish feed. The feed from the modulator and the feeder enters the twin-screw extruder for extruding, and the extruded material is pushed out of the die hole by the twin-screw extrusion. The diameter of the product is adjusted by changing the molds with different apertures, and the thickness of the product is controlled by adjusting the rotational speed of the rotary cutter.

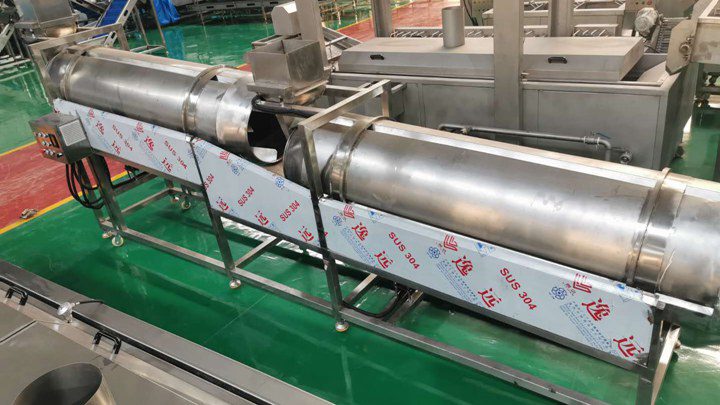

6. High-pressure air conveyor

6. High-pressure air conveyor: It is mainly used to transport fish feed pellets produced by the extruder. With stainless steel pipes, the placement of the fish feed extruder host and fish feed oven can be adjusted at will. Small production lines need to use positive pressure air conveyors, and large fish feed production lines use high-power negative pressure air conveyors as the source of conveying force. The conveying pipeline adopts stainless steel pipe, which can effectively avoid the generation of broken and defective fish feed during the conveying process.

7. Fully automatic fish feed dryer

It is used for drying the moisture of fish feed pellets. The use of a reciprocating mesh belt structure can avoid uneven heating of fish feed. The heating source, it can be divided into two types: gas (fuel) oven and electric heating oven.

8. Hoist

It is used to lift the baked fish feed pellets into the seasoning line. The rib structure can effectively prevent the fish feed pellets from falling.

9. Seasoning machine

The process of seasoning, spraying oil, and adding nutritional additives to the dried fish feed pellets. There are two kinds of equipment: an automatic single (double) drum seasoning line and a semi-automatic star anise seasoning line. The octagonal barrel equipment is cheap, but it needs to artificially add raw materials such as oil and nutritional additives. The fully automatic single (double) drum can realize automatic seasoning and mix without manual intervention.

10. Cooling conveyor

10. Cooling conveyor: used for cooling and final drying of mixed fish feed. The use of axial fans and mesh belt conveyors can meet the forced cooling and drying of fish feed in the later stage, and prevent the occurrence of dampness and hardening of fish feed after bagging.

Fully automatic production line case show