The fish feed product is an important factor in large-scale fish husbandry and monoculture and has a great impact on fish growth effectiveness and monoculture costs. In the once many decades, the use of floating fish feed has increased significantly because it’s a high- quality environmentally friendly fish feed with superior water stability, better floating characteristics, lower pollution, and zero waste. All of these make it an trend for the development of the aquaculture feed industry.

The machine included in the fish feed production line

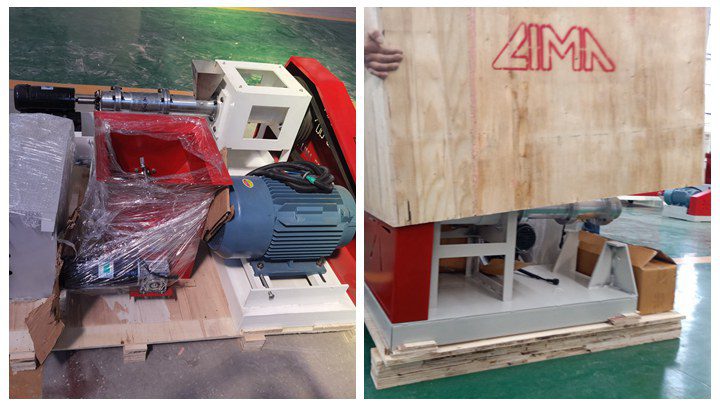

The complete fish feed production line is composed of the hammer mill, crusher, mixer, dryer, cooler and other equipment. It uses corn, straw, grain powder, meal and other grains as raw accouterments to produce high-quality and largely nutritional fish feed.

How to Start a Fish Feed Extruding Factory?

The demand for animal fish feed pellets is fleetly adding. Due to a similar increase, the fish feed extruding machine and feed extrusion product line were developed to prevision that demand. Our outfit and factory have multitudinous specifications which are essential in the product of sinking fish feed, floating fish feed, and pet feed. The outputs for our fish feed machines come in various flavors, shapes, smooth texture, and essential super nutrients. This differentiation is to meet the different fish-eating habits.

Generally, the product line of fish feed includes the process of crushing, mixing, banishing, drying and packaging. There are colorful machines involved in fish feed processing which include the grinder, mixer, fish feed machine( extruder), dryer, and packaging machine.

Our fish feed extrusion machine and factory are completely automated to offer different sizes at a high production rate. The feed pellets produced by our outfit are suitable for feeding Catfish feed, Carp feed, Trout feed, Halibut feed, and so on.

Why choose our floating fish feed-making machine?

the floating fish feed processing machine is acclimated to different product conditions, large and medium-sized feed manufactories can use it for recycling raw material or special feed products. similar to detoxification of puffed full-fat soybean, puffed sludge, cotton mess( or rapeseed mess) or puffed pet feed or other specialty feeds and they can also use this fish feed-making machine as the main outfit to produce full-price extruded feed.

The floating fish feed bullet machine can acclimatize to different accouterments and different product conditions. This fish feed-making machine is equipped with a mechanical confluent and the product volume can be changed according to the situation. According to different puffing conditions, the corresponding extrusion screw group can be flexibly formed and also matched with different outlet parts, which can acclimatize to different processing conditions.

The structure of the floating fish feed machine is simple and practical. The whole machine is exquisite in shape, simple structure, and has easy operation. Advanced technology and humanized design ensures easy operation and dependable performance, Screw sleeve of this floating fish feed product machine adopts enchase alloy steel strip structure, which guarantees long service life, finished pellet can float on water for 24 hours with different size.

Notable Features of Dry Type Fish Feed Extruder Machine

- It’s a low-cost fish feed-making machine and requires lower maintenance.

- You can fluently acclimate the size( diameter and length) of pellets according to your conditions.

- The high temperature produced during the feed pellet manufacturing process is largely effective in destroying the germs present in the raw material.

- High-quality material is used for its construction which increases its life and makes it resistant to damage.

- It’s the most suitable fish pellet-making machine for a small-scale feed shop. You can also use it to make fish feed pellets for your own farm.

- Pellets produced through this machine are of request norms.