There are several reasons why you may want to consider buying a fish feed pellet machine in Nigeria:

- Increased production efficiency: A fish feed pellet machine can help you produce to feed more efficiently and quickly, allowing you to meet the demand for fish feed in Nigeria.

- Improved feed quality: Fish feed pellets produced with a machine are uniform in size and shape, making it easier for fish to consume and digest. Additionally, the machine can help you produce feed with a higher nutrient density, which can improve the overall health and growth of your fish.

- Cost-effective: Fish feed pellet machines can help you save money in the long run by reducing the cost of feed production. The machine can produce feed pellets using locally sourced ingredients, reducing the cost of imported feed.

Overall, the fish feed pellet machine can be a valuable investment for anyone involved in the fish farming industry in Nigeria, helping to increase production efficiency, improve feed quality, and save costs in the long run.

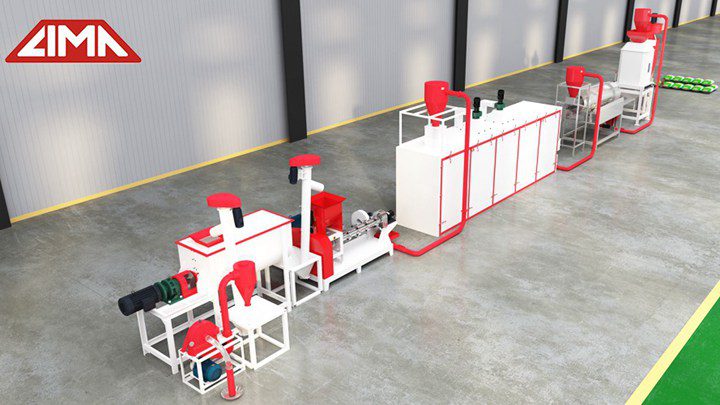

Introduction of the fish feed pellet machine

A fish feed pellet machine is a machine used to produce feed pellets for fish. These feed pellets are made from a mixture of ingredients such as fish meal, cereal grains, soybean meal, and other protein sources. The ingredients are blended together and then compressed into small pellets using the fish feed pellet machine.

Fish feed pellets produced with a pellet machine are uniform in size and shape, making it easier for fish to consume and digest. Additionally, the machine can help you produce feed with a higher nutrient density, which can improve the overall health and growth of your fish.

Fish feed pellet machines can be used by commercial fish farmers, hatcheries, and other organizations involved in the fish farming industry. There are different types of fish feed pellet machines available, ranging from small, manual machines to large, automated machines. When choosing a machine, it’s important to consider factors such as the capacity of the machine, the type of fish you are feeding, and the size of your operation.

Cost of fish feed pelleting machine in Nigeria

The cost of a fish feed pellet machine in Nigeria can vary greatly depending on several factors such as the type of machine, capacity, and brand.

Small, manual fish feed pellet machines can cost anywhere from NGN 100,000 to NGN 300,000. Larger, automated machines can cost several million naira.

It’s important to note that the cost of the machine is just one aspect to consider when buying a fish feed pellet machine. Other factors such as maintenance costs, operating costs, and the cost of the ingredients used to make the feed should also be taken into account.

Lima machinery has been in the fish feed pellet industry for nearly ten years, focusing on the production of fish food extruded pellet machines. In addition, our factory has dozens of different fish feed pellet production line solutions for customers to choose from. After continuous communication with customers, our feed pellet machine has received praise from customers, especially those in Africa and South Asia. If you have any questions, please feel free to contact us, our professional technicians are more than happy to help you.

Where to buy fish feed pellet machines in Nigeria

There are several places where you can buy fish feed pellet machines in Nigeria, including:

- Agricultural equipment suppliers

- Machinery dealers

- Online e-commerce platforms

When buying a fish feed pellet machine, it’s important to compare prices and features from different suppliers to ensure you are getting a high-quality machine at a fair price. I recommend contacting the seller to confirm that they can deliver the machine to your location in Nigeria before making a purchase. Additionally, you may want to consider reading reviews from other customers to get a better idea of the quality of the machine and the reputation of the supplier.

How to choose a suitable fish feed pellet machine for yourself

When buying a fish feed pellet machine, there are several important factors to consider to ensure that you get a high-quality machine that meets your needs. These include:

- Capacity: Consider the size of your fish farming operation and the number of fish you will be feeding. This will help you determine the capacity of the machine you need.

- Type of fish: Different types of fish have different dietary requirements, so it’s important to choose a machine that can produce feed suitable for your specific type of fish.

- Power source: Consider the power source for the machine, as this will impact the cost of operating the machine and its efficiency. Some machines are powered by electricity, while others are powered by diesel or gas.

- Price: The cost of the machine is an important factor to consider, as it will impact your overall investment in the equipment. However, it’s important to not just focus on the initial purchase price, but also consider the cost of maintenance and operating expenses over time.

- Brand reputation: Consider the reputation of the manufacturer or supplier of the machine. This can give you an idea of the quality of the machine and the level of support you can expect after the purchase.

- Technical specifications: Check the technical specifications of the machine, including its size, weight, and power requirements, to ensure that it meets your needs.

- After-sales support: Consider the level of after-sales support offered by the manufacturer or supplier. This can include warranty and maintenance services, as well as technical support and training.

- Ease of use and maintenance: Consider how easy the machine is to use and maintain, as this will impact your overall cost of ownership.

- Warranty: Consider the warranty offered by the manufacturer or supplier, and what it covers in the event of a problem with the machine.

By considering these factors and doing your research, you can ensure that you buy a high-quality fish feed pellet machine that meets your needs and provides a good return on your investment. It’s also a good idea to consult with experienced fish farmers or industry experts for advice and recommendations.